Octal supply API 5L welded (ERW, EFW, LSAW, SSAW) steel line pipe in Gr B, X42, X46, X52, X56, X60, X65 PSL1, PSL2 and for sour service (NACE pipe).

Line pipe brief introduction

API 5L steel line pipe is for oil and gas industries pipelines, developed for different working environments. The steel line pipe material generally in carbon steel and comply to API SPEC 5L specifications.Applied for petroleum and natural gas industries, oil industries requirements for transportation and are expected working in extreme situations, low and high temperatures, corrosion resistance for corrosive environments, and for sour services in H2S conditions.

Welded (ERW, LSAW, SSAW) steel line pipe grade feature

Common Class: API 5L Gr.B PSL1, PSL2, Sour Service pipe

Medium: X42, X46

Medium: X52

Medium and high: X56

High level: API 5L X60 PSL1, PSL2 LSAW line pipe

High: API 5L X65 PSL1, PSL2 LSAW/SSAW line pipe

Premium high: API 5L X70

Premium high: API 5L X80

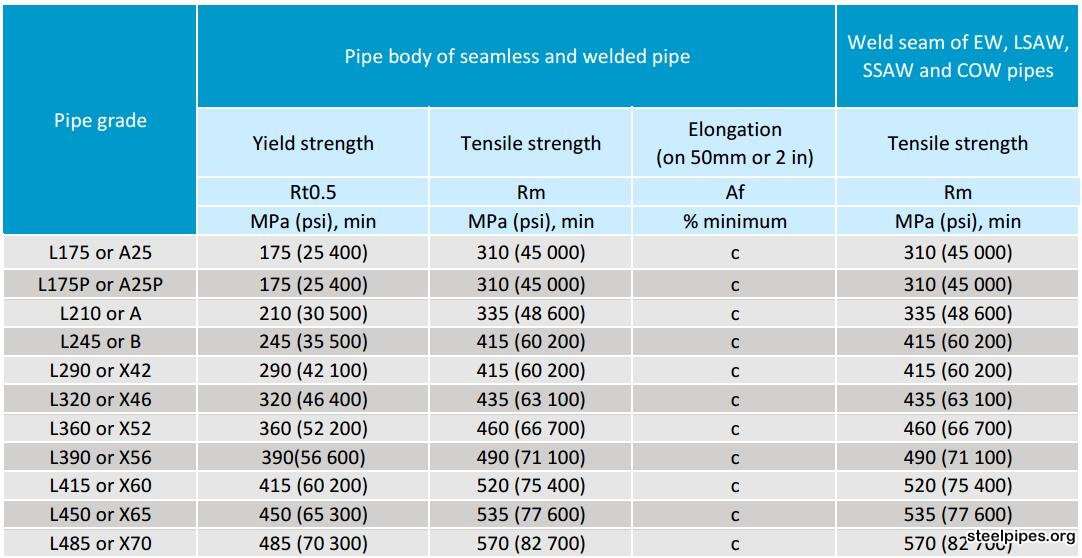

Chemicals composition and mechanical strength

API 5L Welded pipe chemicals has more strict control than seamless. More details about API 5L Seamless please visit here.

API 5L psl1 pipe chemical composition properties

Tensile strength and yield strength is same with API 5L seamless pipe.

Our Supply range for API 5L welded line pipe

Welded (ERW, LSAW, SSAW) steel line pipe: 1/2” to 60”

Range of Thickness: SCH 10 to SCH 160

Ends Type: Beveled ends, Plain ends

Range of length: 20FT, 40FT or customized

Protection Caps in plastic or iron available

Surface appearances: Natural, Varnished, Black painting, 3PE, FBE, etc

Welded Pipe manufacturing types

There are 3 welding types: ERW (Electric Resistance Welding), LSAW (Longitudinally Submerged Arc Welding), and SSAW (Spirally Submerged Arc Welding) welding types.

ERW pipe is a type of Resistance pipe stands apart from welded pipe and DC welded pipe in two different manners as listed below. Based on the welding frequency, the IF welding for low frequency and the ultra-IF welding for high frequency. In case of thin-walled pipe, there is a high frequency weld used typically in case of contact welding and induction welding. When the usage is for a small-diameter pipe, they make use of DC welding. There is a high frequency welding process used to manufacture pipes that are comprehensive and is of ERW type. For oil and gas storage, the best recommended type is ERW longitudinal, owing to its quality, ease of transport and cost.

Both LSAW pipe and SSAW pipe are SAW pipe (Submerged Arc Welding Steel Pipe), is manufactured by making use of a submerged arc soldering process for preparing the steel and it results in high density pipe. Owing to the flux layer, there is no instant heat loss and it gets concentrated near the weld. It results in high quality, highly efficient arc and smoke, which finds intensive usage in pressure vessels, pipe manufacturing, beams, fluids, steel works etc. SAW pipe find its main usage in LSAW pipe, which is Longitudinally Submerged Arc Welding pipe.

ERW welded pipe manufacturing process

ERW process normally applied to the pipe below 24 in, 609 mm.

ERW/HFW Longitudinally Welding Steel Line Pipe (Electric Resistance Welding ) Manufacturing Flow Chart

Uncoiling – Flattening – Shearing and Butt Welding – Loop Storing – Plate UT – Trimming – Forming – High Frequency Welding – Removal of Inside and Outside Blurs – Ultrasonic Testing – Annealed by Medium Frequency – Air Cooling – Water Cooling – Sizing – Straightness – Cutting Off – Dimension and Initial Surface Inspection – Pipe Ends Beveling – Hydrostatic Test – Ultrasonic Testing of Entire Tube – Off Line Ultrasonic Testing – Ultrasonic Testing for Pipe Ends – Dimension and Final Surface Inspection – Corrosion Resistant Coating – Marking – Pipe Ends Protection – Inspection and Warehousing

LSAW pipe manufacturing process

LSAW pipe applied to diameters from 20 in (508 mm) to 40 in (1016 mm).

LSAW Welded Steel Line Pipe Manufacturing Flow Chart:

Plate UT – Vacuum Lifting – Ultrasonic Inspection – Edge Milling – Pre Bending – Type J Forming – Type C Forming – Type O Forming – Tack Welding By CO2 Gas Shield Arc Welding – Tab Welding – Inside Welding – Outside Welding – Removal of Tab Plate – Cleaning – Rounding – X Test – Ultrasonic Testing – Washing Before Expansion – Mechanical Expansion – Washing After Expansion – Straightness – Hydrostatic Test – Ultrasonic Testing – Weld Grinding for Pipe Ends – Mechanical Facing – X Ray Test for Body and Both Ends – Ultrasonic Testing for Pipe Ends – Magnetic Particle Inspection For Both Ends – Weighing and Measuring Length – Product Inspection – Outside Coating – Inside Coating – Marking – Packing and Warehousing

SSAW pipe manufacturing process

SSAW pipe applied for diameters up to 60 in (1524 mm)

SSAW Steel Pipe Manufacturing Flow Chart:

Uncoiling – Flattening – Shearing and Butt Welding – Edge Milling – Preliminary Rolling – Forming – Inside and Outside Welding – Cutting Off – Ultrasonic Testing – X Ray Test – Weld Grinding for Pipe Ends – Expanding at Pipe Ends – Hydrostatic Test – Ultrasonic Inspection – Pipe Ends Beveling – X Test – Production Inspection – Marking – Warehousing

Key differences between SAW (LSAW, SSAW) and ERW pipe

As above manufacturing processes we can see SAW (LSAW, SSAW) and ERW pipes are entirely different right from formation, welding etc. and hence, the performance of both the pipes differ in the following aspects:

1. The surface quality of ERW pipes are better when compared to SAW (LSAW, SSAW) pipes, as they are smooth and have a better finish. In most of the SAW pipes, it is mainly about the weld reinforcement internally and externally.

2. The defects found in ERW pipes are lesser than SAW pipes. As there is a solvent deposit in SAW pipes, it results in more defects apart from the defects in the volume. The defects found in ERW pipes are only confined to wire-line and straight welds and it can be inspected easily. The defects can be noticed easily and the ultrasonic reflection on the surface makes it easier to detect.

3. The residual stress ratio in ERW is lower than SAW pipes. As ERW pipe deformation happens more in ERW followed by a sizing of flat oval, it results in elliptical vertical changes and necking, thereby making the stress smaller. The displacement of ERW pipes was smaller when compared along the axial and transverse incisions for comparison with SAW pipes built using the same material and it was also easy to detect.

4. Although the overall performance of both ERW and SAW pipes are the same, once the pipes have defect, the steel scrap and welding can be done on ERW, while it is not the same in case of SAW, which would result in cracking or corrosion, making the ERW more durable.

Applications of the API 5L welded line pipe

For Petroleum and natural gas industries, steel pipe for pipeline transportation systems.

Octal supplied the pipe complied to the international standard API 5L, which specified requirements for the manufacture of two product specifications levels (PSL1 and PSL2) of welded line pipe for use in pipeline transportation systems in the oil and gas industries.

API 5L Line Pipe Standard Spec

Related post

-

-

May 6, 2015 Structure Steel Seamless Pipe

-

-

Archives

-

Seamless steel pipe

- Line pipe

- OCTG pipe

- Mechanical steel pipe

- Structural steel pipe

- Boiler Tube

- ERW pipe

- SSAW pipe

- LSAW pipe

- Corrosion protection pipe

- Insulated pipe

- Abrasion resistant pipe

- Stainless steel pipe

- API pipe

- ASTM pipe

- Galvanized steel pipe

- Water pipe

- Gas pipe

- Carbon steel pipe

- Alloy steel pipe

- Hot rolled pipe

- black steel pipe

- Flange

Welded steel pipe

Special steel pipe

Pipes

Pipe Fittings

3 Comments

Boiler Tubes ASTM A179 Thchnique: Cold-drawn Size: 8-89*1.5-12mm Type: Seamless .

Cold drawn steel tube Size: OD- 1/8"--3" WT: SCH10s-SCh160 Type: Seamless Delivery Condition: Anti-Oxdation Application: General structure and mechanical purpose Standard: GB/T 8162-2008 Grade of Steel: 10, 20, 35, 45, 40MnZ, 20Cr.

Hot Dip Galvanized Steel Pipe,Outer diameter: 20 ~ 219mm. 2) Wall thickness: 1.0~ 12mm 3) Spec.: Q195, Q215, Q235, Q345 .

Q195 Q235 Steel Pipe,steel pipe welded steel pipe Thickness: 1.5mm - 4.5mm steel pipe Diameter: 20.00mm - 273.00mm Q235 & Q195 .

API 5CT Steel Tube,10#,20#,45#,API N80, API 5L seamless steel tube,OD 25-325mm OD 4-70mm Certificates: API5L,ISO, Payment terms: L/C or T/T. Length:1~15m.

Hot Rolled Carbon Boiler Pipe SCH 40.