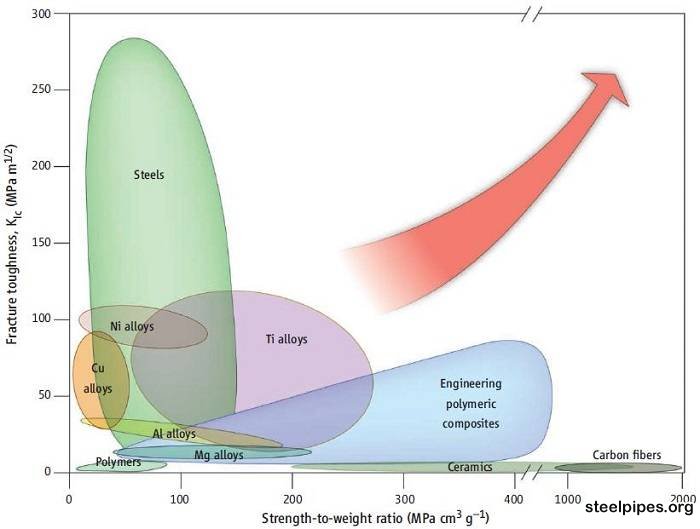

In April 2010, at the invitation of the US Science Magazine, a representative of China’s metal materials research field, director of the National Institute of Materials Science (joint) laboratory of the Institute of Metals of the Chinese Academy of Sciences and an academician of the Chinese Academy of Sciences Lu Ke wrote an article titled “The Future”. "The Forecast of Metals" article. The article believes (refer to Figure 1) that although the proportion of metal in the engineering materials is decreasing due to the lower specific strength and specific stiffness, the application areas where weight is a major consideration (such as aviation and sports equipment, etc.) are gradually being Replaced by other materials, however, due to the unique properties of the metal material itself, such as high strength, high fracture toughness, performance inhomogeneity, predictability of failure strength, unique electromagnetic properties, good in the medium and high temperature range The comprehensive mechanical properties and recyclability of metals are still irreplaceable in many industrial fields, especially in applications requiring high reliability and high durability [1]. The performance of static mechanical properties is one of the important reference factors for evaluating whether a metal material can obtain engineering applications. The material network has collated several common knowledge and test standards for the static mechanical properties of metal materials, hoping to study You can help with the mechanical properties of metal materials.

[Static mechanical properties of metal materials]

The mechanical properties of materials refer to the changes in the state of a material component under load or stress under certain environmental conditions. There are generally three basic types of changes, namely, elastic deformation, plastic deformation, and fracture. Or rupture) [2]. The following describes the tensile, compression, torsion, bending, and hardness properties of metallic materials based on the deformation of static loads.

(1) Stretching

Tensile test is one of the mechanical performance test methods widely used in industry. Its characteristic is that the test temperature, stress state and strain rate are constant. During the test, the load and displacement signals are recorded by the testing machine. According to the size of the sample, the engineering stress-strain curve and the true stress-strain curve can be obtained.

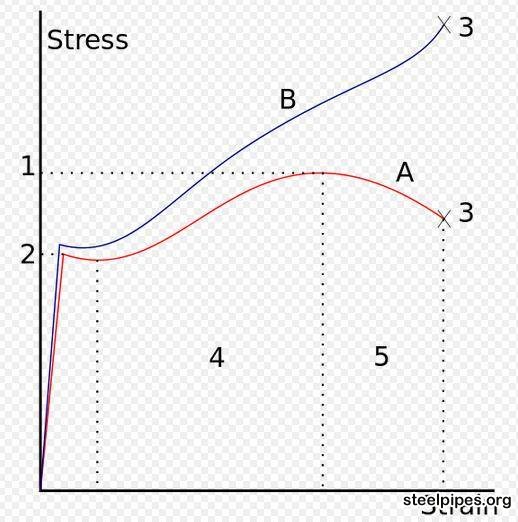

Figure 2 shows a typical structural steel tensile stress strain curve [3], where the red line A represents the engineering stress-strain curve and the blue line B represents the true stress-strain curve. We can see that at the beginning of the stretching process, the stress and strain of the material maintain a linear increase in synchronization, the material is in the elastic deformation stage (deformation can fully recover after unloading), until the stress reaches point 2, the material yields, at this time The stress value is the yield strength of the material, and then the material enters the plastic deformation stage (the deformation cannot be fully recovered after unloading), and the stress slowly increases with the increase of the strain, showing a certain degree of work hardening (area 4). When the engineering stress reaches the maximum strength point 1 (the ultimate strength), it begins to decrease and the material appears necking (area 5) until the final break (point 3).

According to the tensile stress-strain curve of the material, some basic mechanical properties of the material can be obtained, among which the more commonly used indicators and their definitions are as follows:

(1) elastic modulus: the slope of the elastic phase of the engineering stress-strain curve;

(2) Yield strength: The resistance that reflects the material's resistance to plastic deformation is the sign of the material entering the plastic deformation from the elastic deformation. For materials with obvious yielding effect during the drawing process, the engineering stress-strain curve is obvious. The yield stress of the yield effect is used as its yield strength (such as annealed mild steel). For materials that do not have a significant yielding effect during the tensile process, the yield strength is generally replaced by the nominal yield strength, that is, the corresponding participation in the engineering stress-strain curve. Stress at a strain variable (typically 0.2%);

(3) Ultimate strength: The maximum plastic deformation resistance of a representative material is the maximum engineering stress achieved in a tensile test;

(4) plasticity (plasticity): Refers to the ability of the material to undergo plastic deformation, consisting of two parts: uniform plastic deformation and non-uniform plastic deformation. The plasticity index can generally be expressed as total elongation and reduction of area.

(2) Compression

The mechanical properties defined in the metal tensile test and the corresponding calculation formula are basically applicable in the compression test. However, when a uniaxial compressive load is applied to a specimen, the softness factor of the stress state is significantly greater than that of the tensile state, making some materials that show brittle fracture in the tensile test (such as gray cast iron, ceramics, amorphous alloys, etc.) The compression test may show some plastic deformation or show high strength. Therefore, in the study of the deformation and fracture behavior of brittle materials, compression tests are often used to measure their strength and plasticity. Compressed specimens are generally round or square in cross-section.

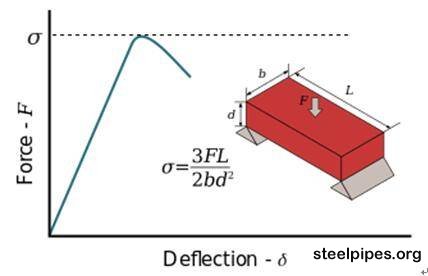

(3) Bending

The bending test is generally used for materials that are relatively brittle and difficult to be processed into a stretching rod, such as ceramics, glass, etc. It has a simple shape, easy operation, and the like. In addition, the maximum surface stress of the specimen during the bending test can react sensitively to the surface defects of the material and is often used to study the surface hardening process and surface properties. Figure 3 shows a typical three-point bending test loading and recorded deflection curve of the load [4], the dotted line corresponds to the stress value of the material is the flexural strength (flexural strength or bend strength).

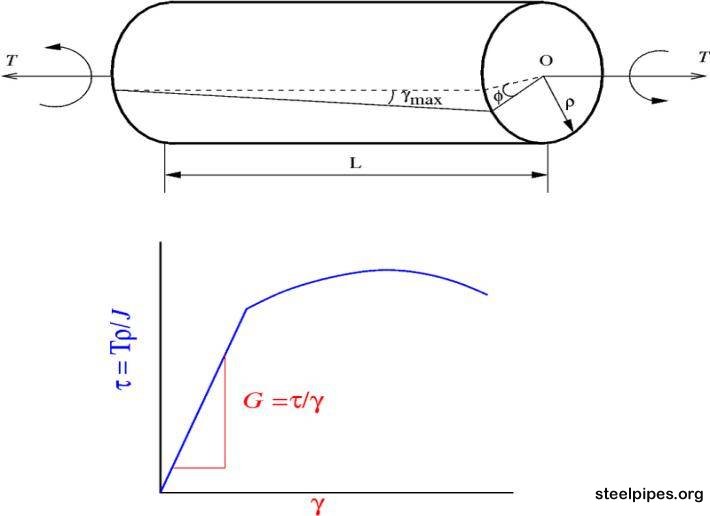

(4) Reverse

The torsion test can achieve high strain and easily show the metal's plastic behavior, especially the plastic properties of metal materials that are brittle when stretched. It can also more sensitively reflect the surface defects of the metal and the properties of the surface hardened layer. The sample used is a cylindrical sample. The plastic deformation of the entire sample length during the experiment is uniform and there is no necking. Figure 4 shows the common torsion test and torsional stress-strain curve diagram [5]. By applying a torsional load to the specimen and recording the torque and torsion angle, the torsional stress-strain curve is obtained, from which the shear modulus of the material can also be obtained. (shear modulus).

(5) Hardness

Hardness is characterized by the ability of a solid material to resist local deformation, particularly plastic deformation, indentation or scratches, reflecting the degree of softness and hardness of the metal material. Because it is convenient and quick to determine the hardness, and can sensitively reflect the difference in the structure of the material, it is widely used to check the quality of the heat treatment process or to study the heat treatment phase change process. It is also commonly used to check the changes in the surface structure of the metal surface and surface properties. . The hardness test methods can be divided into press-in method, elastic rebound method and scratch method. The following are briefly introduced [6]:

(1) The

(2) Elastic rebound method

(3) Scratch method

Figure 5 shows several common hardness measurement devices. It should be pointed out that the physical meaning of hardness varies with the type of hardness test method. Therefore, according to different materials, shapes, sizes and problems to be studied, it is necessary to clarify the test principle, grasp the scope of application and test characteristics, so as to choose The correct hardness test method is to be tested.

[Related test standards summary]

The absence of rules is not a matter of radius. Therefore, in order to test the static mechanical properties of the metal materials mentioned above, it is necessary to observe the corresponding test standards. Xiao Bian has compiled some test standards related to the static mechanical properties testing of metallic materials in the national standard, including:

Needy readers can click to download. ( link: https://pan.baidu.com/s/1eRDBO9W password: bhm5 )

【references】

[1] K. Lu, The future of metals, Science, 2010.

This article was contributed by Zhang Jinrui, academic dry goods group of Material Editorial Department, and edited and edited by cattle.

Material Rennet specializes in tracking material science and technology and industry progress. This brings together major colleges and universities, masters, front-line scientists and industry practitioners. If you are interested in tracking the progress of materials technology, interpreting high-level articles or commenting on the industry's interest , point me to join the editorial department .

In order to submit contributions to the teams, we will be able to contribute to the latest achievements, orientation, team interviews, and experimental skills. Once the excellent manuscripts are accepted, we will receive a reward. Please contact: [email protected] or QQ: 97482208.

Equipment, reagent consumables, material testing, data analysis, finding materials , testing valley !

Academic dry metal materials static mechanical properties and test standards

Fig.1 Fracture toughness-specific strength diagram of common materials[1]

Fig.1 Fracture toughness-specific strength diagram of common materials[1] Fig. 2 Tensile stress-strain curve of a typical structural steel [3]

Fig. 2 Tensile stress-strain curve of a typical structural steel [3] Figure 3 Load Deflection Curve for Loading and Recording of Bending Test [4]

Figure 3 Load Deflection Curve for Loading and Recording of Bending Test [4] Fig. 4 Torsional test loading and torsion stress-strain curve diagram [5]

Fig. 4 Torsional test loading and torsion stress-strain curve diagram [5]

most commonly used press-in method for production is the static load press hardness test because the softness factor of the stress state of the test method is larger than that of the unidirectional compression. Almost all metal materials can produce local plasticity. Deformation, hardness measured by press-in method is mainly divided into three types, namely Brinell hardness (HB), Rockwell hardness (HR) and Vickers hardness (HV). Among them, the Brinell hardness is measured by dividing the test force by the area of the indentation ball, and is generally used for softer materials such as non-ferrous metals and steels before or after heat treatment; Rockwell hardness is the depth of indentation To measure the hardness, it is widely used in the quality inspection of heat treatment; Vickers hardness test has a wide measurement range and covers almost all kinds of materials.

The hardness measured by this method is called the Shore Hardness (HS). It is a dynamic load test method. The principle is to apply a certain weight of a hammer with a diamond round head or steel ball from A certain height falls on the surface of the metal sample, and the metal hardness value is characterized according to the height of the rebound of the weight. It is also called rebound hardness.

The hardness measured by this method is called Moh’s hardness. It uses a scratch method to mark the surface of the test sample with a pyramid-shaped diamond burr. The depth of the scratch is measured in ten points. Grades represent the hardness, which is generally used to measure the hardness of materials such as minerals or gems. Figure 5 Several common hardness measuring devices

Figure 5 Several common hardness measuring devices

GB-T 228-2002_Test method of tensile test at room temperature of metallic materials

GB-T 4338-2006_High-temperature pull of metallic materials tensile test method "

" GB-low T 13239-2006_ metal material tensile test method "

" GB-T 2039-1997_ metal tensile creep and rupture test method "

" GB-compressed materials at ambient temperature T 7314-2005_ Test method "

GB-T 232-1999_ bending test method for metallic materials"

"GB-T 244-2008_ bending test method for metal tubes"

"GB-T 14452-1993_ test method for mechanical properties of metal bending"

"GB-T 10128-2007_Metallic Materials Room Temperature Torsional Test Method 》

GB-T 239-1999_ Metal Wire Twist Test Method

》GB-T 6400-2007_ Metal Materials Wire and Rivet Shear Test Method

》 GB-T 4341-2001 _ Metal Shore Hardness Test Method 》

GB-T 230.1-2009_ Rockwell Hardness Test of Metal Materials_ Part 1 - Test Method

》 GB-T 231.1-2009_ Brinell Hardness Test of Metal Materials - Part 1 - Test method "

" GB-T 4340.1-2009_ metal material Vickers hardness test _ 1 Points - Test Methods "

[2] Yang Wangxi, Qiang Wenjiang et al., Mechanics of Materials Mechanics, Chemical Industry Press, 2009.

[3] Beer F., Johnston R., Dewolf J. , Mazurek D., Mechanics of materials, McGraw-Hill companies, 2009.

[4] Michael Ashby, Materials selection in mechanical design, Butterworth-Heinemann, 2011.

[5] Case John, Ross Carl, Chilver Lord, Strength of Materials and Structures, Elsevier, 1999.

[6] Zhang Zhefeng, Handbook of Materials Mechanics, Institute of Metals, Chinese Academy of Sciences, 2014.

Related post

Archives

-

Seamless steel pipe

- Line pipe

- OCTG pipe

- Mechanical steel pipe

- Structural steel pipe

- Boiler Tube

- ERW pipe

- SSAW pipe

- LSAW pipe

- Corrosion protection pipe

- Insulated pipe

- Abrasion resistant pipe

- Stainless steel pipe

- API pipe

- ASTM pipe

- Galvanized steel pipe

- Water pipe

- Gas pipe

- Carbon steel pipe

- Alloy steel pipe

- Hot rolled pipe

- black steel pipe

- Flange

Welded steel pipe

Special steel pipe

Pipes

Pipe Fittings

3 Comments

DIN1629 St52 seamless pipe,PRODUCTS: DIN1629 St52 seamless pipe, DIN1629 St52 seamless steel pipe, DIN1629 St52 seamless tube, DIN1629 St52 seamless steel tube.

Processing performance [1] Cutting seam fine: laser cutting slit is generally in 0.10~0.20mm. Cutting thickness: Stainless steel 0.5-8mm, carbon steel 0.5-22mm [2] Smooth cutting surface: laser cutting surface without burrs, no need to deal.

Large-diameter seamless pipe, ASTMSEAMLESS STEEL PIPE ,ERWSTEEL PIPE ,SEAMLESS STEEL PIPE ,SPIRAL WELDED STEEL PIPE .SPECIFICATION: 1/2" 3/4" 1"1 1/4" 11/2"2"2 1/2" 3"3 1/2"4"5"6"8"10"12"14"16"18"20".22"24"26".28".30"32"34" ..NOMINAL WALL TH.

DIN seamless gas pipe,Our company is a professional export business corporation.We export seamless steel pipe,carbon steel pipie staight steel pipe ,ERW steel pipe ,galvanized steel piipe and Large diameter steel pipe.we have high quality.

Steel pipe weld welding,Welding is a professional, highly normative work in the steel construction is very important, therefore, as a key in the bridge steel arch ribs processing monitor the entire process..

ASTM A213 gas pipe 1.OD:2 3/8"-6 5/8" 2.Grade:E,X,G,S 3.Upset:IU,EU,IEU 4.HB:Arnco100XT,150XT,300XT, Botn1000,3000 5.IPC:TC.